In modern automation and motion control systems, achieving precise control over speed, position, and torque is essential for optimal performance. Servo drives for motion control provide the accuracy and reliability needed for a wide range of applications, from robotics and CNC machinery to material handling systems. These drives are crucial in managing motor functions with precision, ensuring high efficiency in complex, high-performance tasks. Let’s learn about the role of servo drives for automation, how they work, and the benefits they bring to motion control systems in various industries.

What are Servo Drives?

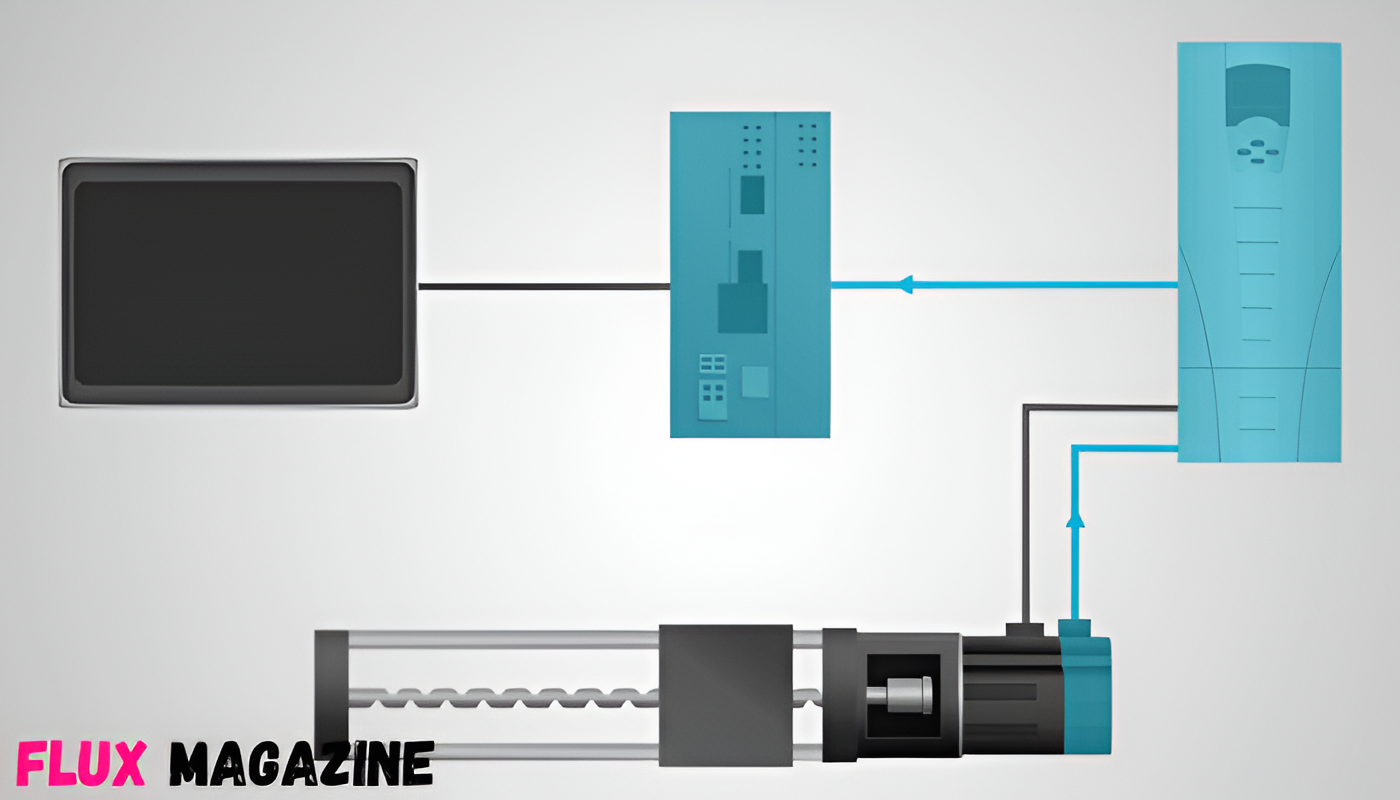

A servo drive is an electronic device designed to control the motion of an electric motor with high precision. It works in tandem with a servo motor, creating a closed-loop system that ensures the motor’s movement is continually adjusted based on feedback signals. This setup is used in industries like robotics, manufacturing, and material handling, where high accuracy is required.

By receiving control signals from a controller, the system regulates the motor’s speed, position, and torque. Feedback mechanisms, like encoders, monitor the motor’s performance, allowing for real-time adjustments to maintain optimal motor function.

How do Servo Drives Work?

They function by receiving control signals from a motion controller, such as a Programmable Logic Controller (PLC). The servo drive then adjusts the motor’s electrical current to meet the desired motion requirements. Feedback signals from an encoder or resolver continuously inform the drive about the motor’s position and speed.

This closed-loop system ensures the motor’s performance is continually adjusted to achieve high precision. Through real-time corrections, these drives guarantee that the motor operates within specified parameters, preventing issues such as overheating, underperformance, or inaccuracies.

Key Benefits of Using Servo Drives for Automation and Motion Control

Here are the benefits that these drives offer in industrial systems:

High Precision and Accuracy

The main advantage of servo drives is their ability to control speed, torque, and position with exceptional precision, ensuring minimal deviation from the set parameters. This makes them perfect for applications requiring tight tolerances, such as CNC machining, 3D printing, and robotics.

Energy Efficiency

Compared to traditional systems, these drives are more energy-efficient. They use only the necessary power for the task, reducing operating costs and enhancing overall system performance.

Enhanced Speed Control

These systems allow for rapid acceleration, deceleration, and precise speed regulation, ensuring smooth motion in applications like packaging, conveyors, and robotic arms, thus improving throughput and minimizing cycle times.

Smooth Motion and Reduced Wear

The precise control from servo drives ensures smooth operation, preventing sudden starts or stops. This reduces mechanical stress on components, extending the lifespan of equipment and lowering maintenance costs.

Compact Design

Modern systems are compact, easily integrated into existing setups, whether for small robots or large industrial machines. This flexibility allows them to handle various motor sizes and power levels.

Advanced Diagnostics and Feedback

Many servo drives come equipped with advanced diagnostic features that provide insights into motor performance, enabling early detection of issues and preventing downtime and improving reliability.

Customization for Specific Applications

These systems are highly customizable, with adjustable parameters like speed and torque to meet the demands of different tasks, making them ideal for industries like packaging, robotics, and precision manufacturing.

Improve Your Automation with Servo Drives

Integrating servo drives into your automation systems can greatly enhance precision, efficiency, and overall reliability. Their ability to precisely control speed, torque, and position makes them crucial for high-performance applications in robotics, CNC machining, and other motion-control systems.

For businesses aiming to optimize motion control, servo drives offer an energy-efficient, dependable, and cost-effective solution. Partnering with a trusted brand ensures that your systems are equipped with top-quality servo drives to meet your automation requirements.

Show Comments (0)